In its latest funding round, the US Department of Energy (DoE) has allocated millions for truck original equipment manufacturers (OEMs) like Cummins and Paccar to invest in battery research. The objective is to drive down electric truck battery prices and advance the adoption of electric vehicles (EVs) in the transportation sector.

Out of the DoE funds, $60 million is designated for the United States Advanced Battery Consortium to enhance the development of lightweight, cost-effective batteries for light, medium, and heavy-duty vehicles. Additionally, these funds will support the research into more affordable battery recycling processes.

The remaining $71 million will be distributed among 27 other projects, each concentrating on extending driving range, reducing battery costs, and progressing on-board EV charging systems and telematics. Noteworthy among these projects are battery technology startups Lyten and Zeta Energy, along with manufacturing company Coherent, which are notable for their focus on lithium-sulfur batteries.

Each of these three companies has received over $3 million to specifically advance lithium-sulfur battery technology. According to researchers at Argonne National Lab, lithium-sulfur batteries have the potential to be more cost-effective to produce than ion-based batteries while also offering superior energy density compared to conventional lithium-ion batteries.

Despite these positive developments, there are challenges and concerns that need to be considered.

Hydrogen gets a boost, too

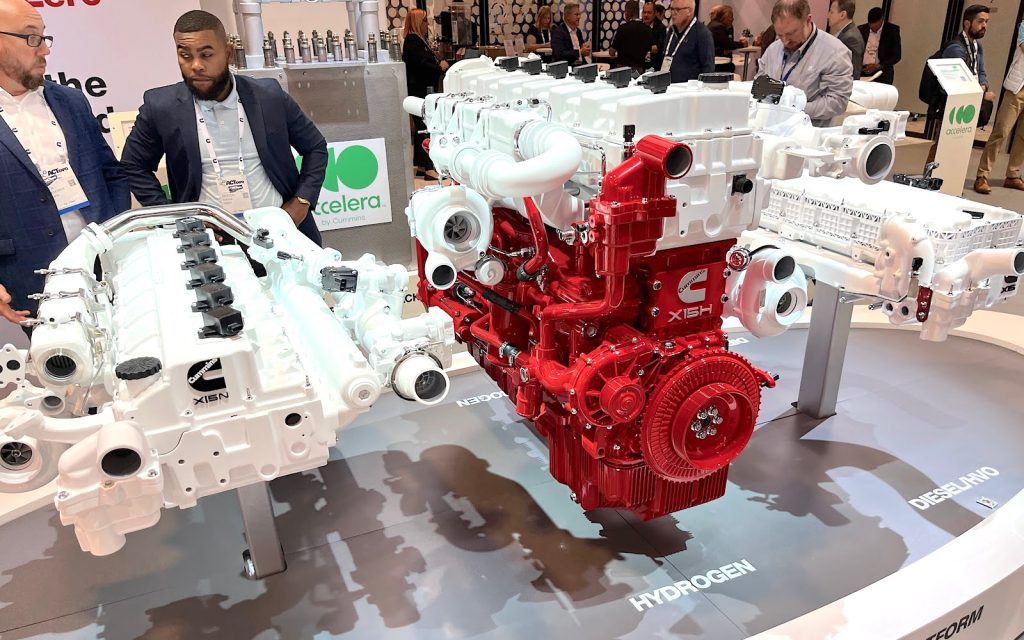

Despite several studies and the skepticism of certain smart truck manufacturers dismissing hydrogen as a viable transport fuel, diesel engine manufacturers Cummins and Paccar have been granted $3.5 million each for research and development focused on hydrogen internal combustion engines for heavy-duty vehicles.

Cummins has demonstrated both full and blended-hydrogen combustion engines in recent years. The newly introduced 15L Cummins engine has the capability to operate effectively on diesel, blended hydrogen, compressed natural gas, or pure hydrogen, all from the same base, allowing the engine manufacturer to quickly adapt its assembly lines to meet market demands as the fueling infrastructure evolves.

In addition to the $3.5 million for hydrogen internal combustion engine research, Cummins has been awarded an extra $5 million to work on developing a wireless charging solution for heavy-duty vehicles.

0 Comments